In China, iron oxide pigments are widely used in construction materials, coatings, cosmetics, rubber, plastics, papermaking, ceramics and other industries due to their excellent performance, among which coatings account for the largest consumption share. In the first half of 2025, both the production and sales volume of iron oxide pigments in China showed an upward trend, while the export demand declined slightly. At present, the production methods of the industry are diversified, with the wet process as the mainstream. Driven by the dual requirements of environmental protection and energy consumption control, the industry is actively transforming towards a green development direction.

Coatings: The Largest Downstream Consumer Market for Iron Oxide Pigments

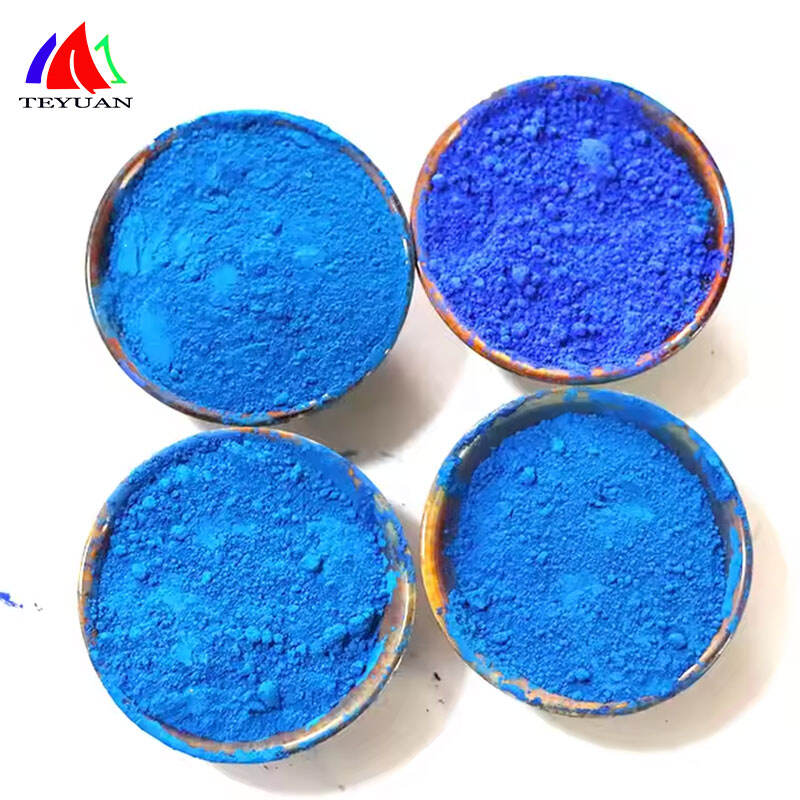

Iron oxide pigments are inorganic pigments with iron oxides and their hydrates as the main components, including multiple categories such as iron oxide red, iron oxide yellow, iron oxide black, and iron oxide brown. Due to their excellent weather resistance, chemical stability, rich colors, and environmental friendliness and non-toxicity, iron oxide pigments are widely used in construction materials, coatings, cosmetics, rubber, plastics, papermaking, ceramics and other industries in China. Among them, the coating industry is the largest downstream consumer market for iron oxide pigments. Data shows that in 2023, the sales volume of iron oxide pigments in China's coating industry reached 116,000 tons, accounting for 43.9% of the total sales volume of iron oxide pigments, highlighting its core position.

Downstream Application of Iron Oxide Pigments

Downstream Sectors |

Main Applications |

Construction Materials |

Iron oxide pigments are used in pavement bricks, permeable bricks, decorative blocks, etc., providing natural colors such as red, yellow, brown, and black, with UV resistance and no fading; some modified asphalt rolls use iron oxide pigments for surface coloring; stone-like products: by adjusting the color of iron oxide pigments to simulate the texture of natural stone, reducing costs, etc. |

Coatings |

Iron oxide pigments are widely used in high-end automotive coatings, architectural coatings, anti-corrosion coatings, powder coatings, etc. |

Cosmetics |

Iron oxide yellow, with bright color, high tinting strength and covering power, as well as light resistance, alkali resistance and heat resistance, is mainly used in beauty cosmetics such as foundation cream; iron oxide red, non-toxic and tasteless, with strong tinting strength and covering power, is mainly used in beauty cosmetics such as greasepaint and foundation cream; chromium oxide green, with metallic luster, strong covering power and good fastness, is used in eye beauty cosmetics, etc. |

Rubber |

Iron oxide red pigment can be used as a colorant in rubber products such as tires, seals, and shoe soles. |

Plastics |

Iron oxide pigments are mainly used for coloring and functional modification in plastics. |

Papermaking |

In the papermaking process, iron oxide pigments can be used for paper coloring to improve the aesthetics and quality of paper. |

Ceramics |

Iron oxide pigments can be used for coloring ceramic products. They present various colors such as red, yellow, brown, black, and purple, providing a rich color selection for ceramic products. |

In the coating field, iron oxide pigments have a wide range of application scenarios, covering high-end automotive coatings, architectural coatings, anti-corrosion coatings, powder coatings and other categories. China is the world's largest coating producer. Since 2021, the coating output has remained above 34 million tons, providing a solid demand foundation and significant market space for the iron oxide pigment industry.