Cobalt blue is an important inorganic pigment with a Pigment Index Number of Pigment Blue 28, abbreviated as P.B.28.

Cobalt blue has excellent high-temperature resistance. It has a high melting point (above approximately 1400°C) and can maintain color stability without decomposition or fading during high-temperature firing processes (usually 800-1300°C) such as in ceramics and glass production, making it a key blue pigment in high-temperature fields.

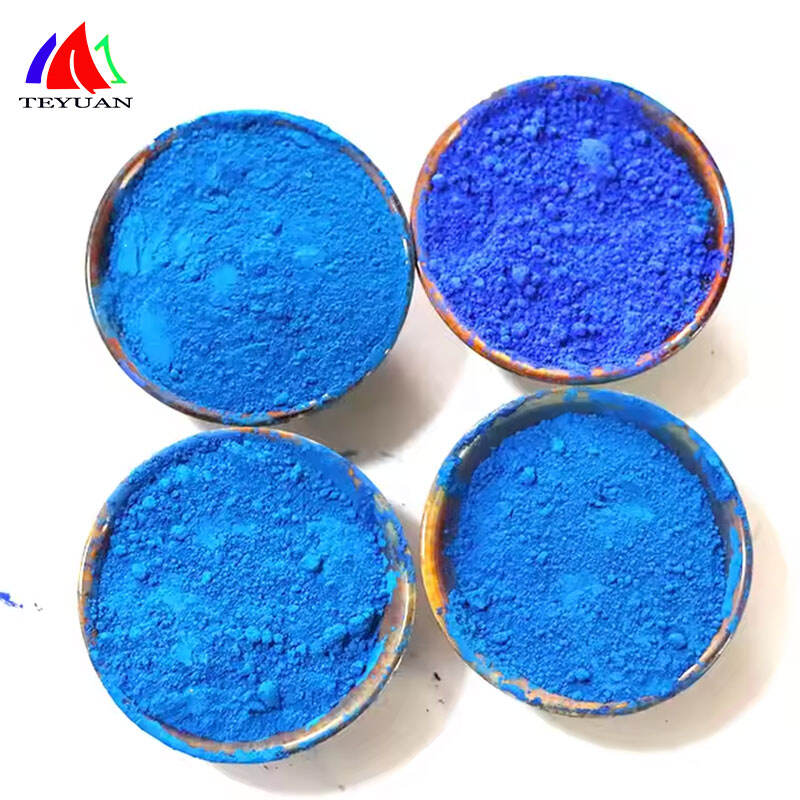

Cobalt blue can be divided into light cobalt blue, medium cobalt blue, and dark cobalt blue based on the depth of its color.

Light cobalt blue: It has a bright blue or sky-blue hue, with a lower cobalt content or doped with zinc elements. It is suitable for occasions requiring bright blue (such as plastic toys and light coatings).

Medium cobalt blue: It has a pure blue hue with high saturation and is the most widely used (such as ceramic glazes and oil painting pigments).

Dark cobalt blue: It has a higher cobalt content or doped with nickel, presenting a deep hue close to navy blue. It is applicable to scenarios needing a calm blue color (such as high-end coatings and industrial enamel).

Compared with phthalocyanine blue (organic): Cobalt blue is an inorganic pigment, and its high-temperature resistance is far superior to that of phthalocyanine blue (phthalocyanine blue usually resists temperatures of around 300°C). However, its tinting strength is slightly lower, and its cost is higher.

Compared with ultramarine (inorganic): Cobalt blue has a more pure blue hue, while ultramarine has a purplish tint; cobalt blue has better acid resistance, whereas ultramarine is easily corroded by acid.

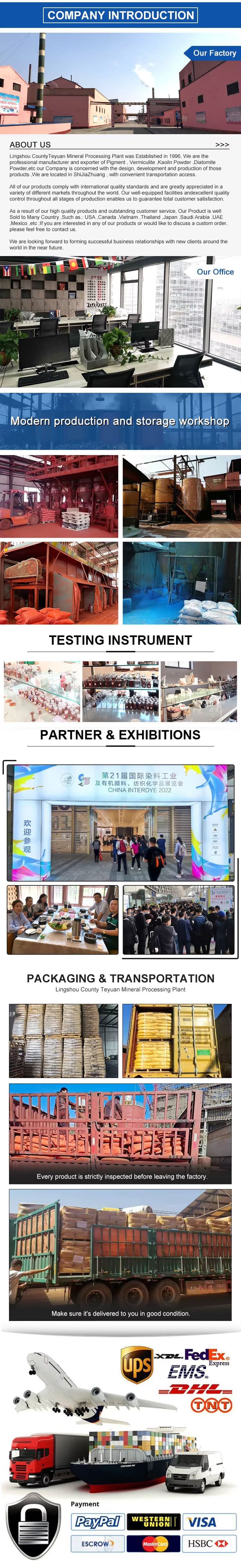

Due to the scarcity of cobalt as a metal, the cost of cobalt blue is relatively high. Nevertheless, its irreplaceable high-temperature stability and color characteristics enable it to be widely used in high-end fields.